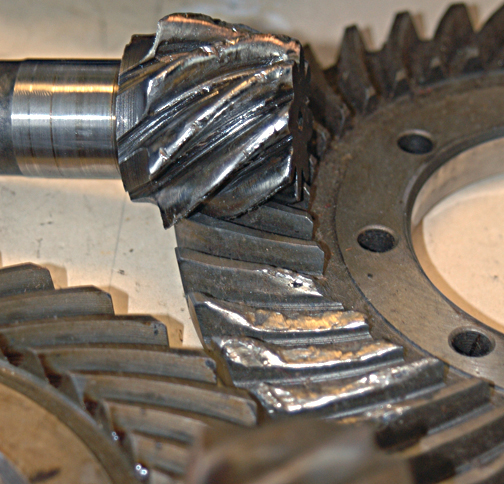

The TA has a conventional rear axle with power supplied from the drive shaft to the Pinion which turns the Crown Wheel, which drives the spider gears, which turn the half shafts. Simple enough.

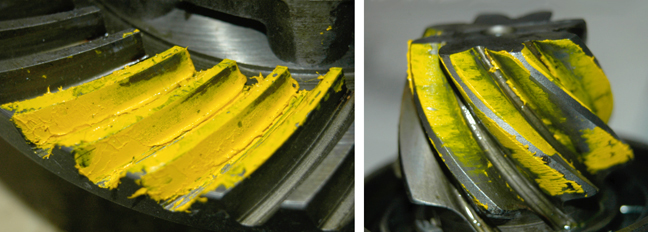

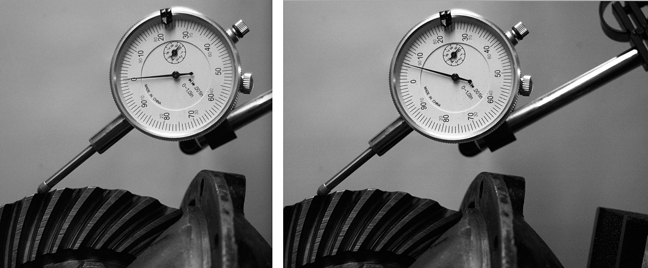

The Crown Wheel & Pinion are where the final drive ratio is determined. Originally this ratio was 4.875 to 1, in other words for every rotation of the rear wheel the drive shaft has to make almost 5 rotations. 4.875 to be exact. It's also known as an 8/39 diff. The Pinion having 8 teeth and the Crown Wheel 39. Other ratios can be, and were, used in the early days especially for Trials cars. By replacing the original with a lower ratio (a higher decimal number!) more torque would be delivered to the rear axle giving it an advantage over the 8/39 when climbing a hill. The trade-off however is that the engine spins much faster at road speed and can not achieve as great a top speed as with the the original ratio. It's good to keep in mind that "sports cars" of this type and of this era were just that. Sports Cars! They were not coddled or hauled to and from an event in an enclosed trailer in search of cups and trophies. The awards they won were earned by virtue of their abilities and reliability most often under rather harsh conditions. And while there are still, relatively speaking, several TAs (and other prewar MGs) on the road, very few are actively campaigned with the same vigor and enthusiasm that they were in the mid-late 1930s when they were 'new'. Today, with better road conditions and higher speed traffic the focus for many of us is trying to squeeze out a few more miles per hour and at the same time reduce our MPJG's revs per minute. And doing so without putting undue stress on the engine or sacrificing its reliability. Since these gear sets can be exchanged with relative ease some owners increase the ratio giving a higher (theoretical) top speed but more importantly this decreases the rpms that the engine has to make to deliver a higher miles per hour. For that reason our 4.875 TA differential is highly favored by TC owners who seek 'longer legs' than the 5.12 to 1 gearing which came standard on their cars. Although the CW&P exchange is the simplest way to change ratios, some have used complete differentials (sometimes called pumpkins) from other make and models of cars. While they may line up with the axle half shafts in the diff casing, they will have to have their matting surfaces machined to match the standard TA axle housing. Axle half shaft splines may also differ and have to be replaced. Although this is a much more complicated approach the primary advantage is that a greater selection of ratios are available when going that route. 8/37 - A HIGHER RATIO FOR THE TA The TA Workshop Manual states that in top gear the standard 8/39 (4.875:1) differential delivers 16.67 miles per hour per 1000 rpm. Also bear in mind that when new top speed for a TA was "77 to 80" mph (4,619 rpm to 4,799 rpm). So where does this (and a higher ratio) fit in the real world? Sometime back I asked several TA owners what they felt was a Safe Maximum RPM/Speed for their car. Of those who replied (I believe) all were running a standard ratio differential and 4.50x19 tyres. For one owner 3,000 rpm (50 mph) was a maximum while another said he "very rarely" exceeds 4,000 rpm (66.68 mph). Most said their 'cruising' speed was between 55 and 60 mph (3,300 to 3,600 rpm). Thus the majority of that small study felt 3,500 rpm (58 mph) with occasional bursts higher would be the answer. But almost to a man, everyone said that at 50 mph (3,000 rpm) their engine was happy and felt at that speed it would run forever. And even though Blower lists our Brake Horsepower to be 50 at 4500 RPM few now days seem willing to push their engine into that range. So to gain a few miles per hour without stressing the engine a CW&P change is in order. The 8/37 (4.625:1) CW&P set is the simplest solution and is available from several sources in both UK and Stateside. These gears are a direct replacement for the standard set and will drop engine speed from 3,000 to slightly more than 2,800 rpm when traveling 50 mph. This is about a 5.4% increase in miles per hour per 1,000 rpm over the 8/39 gear set and theoretically works out to be almost 53 mph @ 3,000 rpm; |